|

|

|

| RU |

|

Login

Newsletters

There is no newsletter category found. Information

|

Convenient software simplifies EMI measurementsThe new R&S ® ES-SCAN precompliance software is a user-friendly and cost-efficient tool for computer-controlled EMI measurements with the R&S ® ESPI3 (FIG 1) and R&S ® ESPI7 test receivers. It simplifies and speeds up both lab-based precompliance measurements and the preparation for the final certification measurement.

FIG 1 R&S ® ESPI3 precompliance test receiver. Avoiding expensive follow-on developments …The trend of performing fully automatic software-controlled measurement sequences is widespread in the field of EMI measurements. Many certification measurements run fast and accurately on computer-controlled EMI test systems [1]. However, EMI measurements do not start only when a product is to be certified; EMC aspects must be considered early on to ensure electromagnetic compatibility. But extensive software system solutions for product certification do not focus on quick overview measurements during the development phase of a product. The use in labs calls for easy operation, minimum measurement time and low costs. … by using powerful precompliance softwareRohde & Schwarz has designed its new economical R&S ® ES-SCAN EMI precompliance software – the successor of the R&S ® ESxS-K1 EMI software – specifically for lab-based measurements during the product development phase. This 32-bit software runs under Windows® XP SP2 and supports the R&S ® ESPI3 and R&S ® ESPI7 precompliance test receivers [2]. The software proves its powerful capabilities through the fast and uncomplicated acquisition, evaluation and documentation of RFI voltages, powers and field strengths. Its well arranged and clearly structured user interface provides only those functions that are required for diagnostic and preview measurements; the software does not include the remote control of mast, absorbing clamp/slideway and turntable systems as its functionality has specifically been tailored to development lab requirements. The development-related examinations and precompliance measurements are performed either interactively or automatically in line with commercial EMC standards; the computer-controlled process ensures reproducible results. The easy-to-program software saves valuable development time and costs as it performs measurements efficiently and economically and offers numerous advantages:

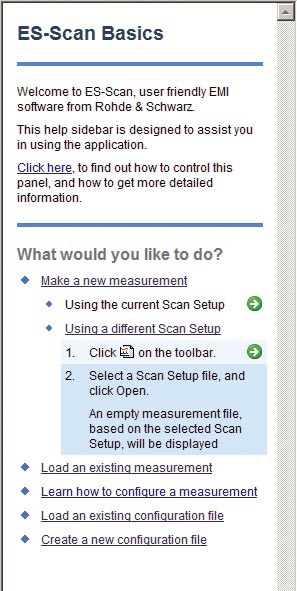

Measurements and documentationThe precompliance software sets all parameters for a measurement at the R&S ® ESPI test receiver (e. g. frequency range, measurement bandwidth, step width, measurement time) and collects and analyzes the data obtained. The intuitive graphical user interface is clearly and logically structured; even newcomers or occasional users operate it quickly and correctly so that they can fully concentrate on their measuring tasks. The extensive context-related help function offers further support in case of questions. In addition to catchword and index search, it also features a measurement wizard that guides the user, if required, through all phases of the measurements (FIG 2). This ensures optimum support when EUTs are examined and evaluated – without time-consuming flicking through the user manual.

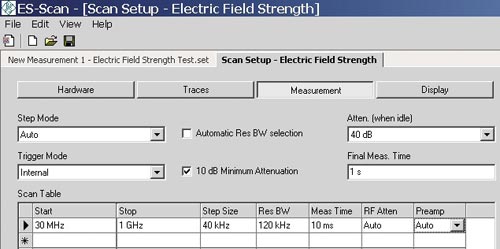

FIG 2 An optional assistant (Help Sidebar) guides the user conveniently through all phases of a measurement. The input masks for the frequency scan table and the associated receiver settings are clearly visualized (FIG 3). The software displays the results in tabular and graphical form; marker and zoom functions support the precise evaluation of the graphically displayed values (FIG 4).

FIG 3 Input mask for scan table and receiver parameters. An automatic setting in line with the CISPR standard may be preselected (Automatic Res BW selection; Auto step mode).

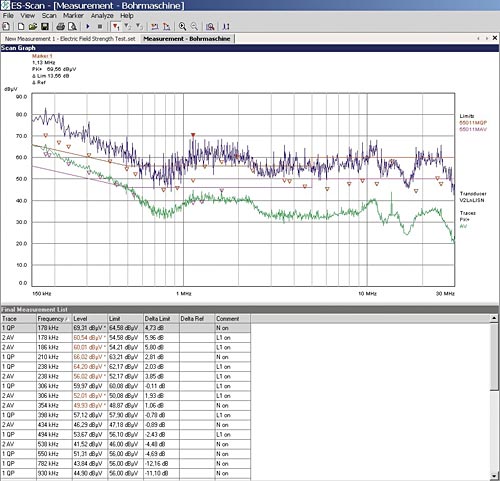

FIG 4 Result of an RFI voltage measurement in the range 150 kHz to 30 MHz: preview measurement (graphics: PK+ and AV) and final measurement (graphics and table: QP and AV) with automatic phase switchover of the line impedance stabilization network (Comment column) via the R&S ® ESPI test receiver. Predefined limit lines, transducer tables and default measurement settings for a large variety of commercial EMI standards are further advantages. An R&S ® ES-SCAN measurement sequence typically consists of several phases:

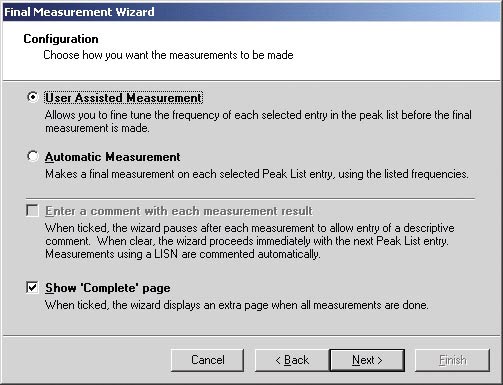

FIG 5 The Final Measurement Wizard provides both an automatic and an interactive (User Assisted) procedure for the final measurement. Two final measurement modes are available for selection (FIG 5). In the Automatic Measurement mode, the software processes the peak value list step-by-step and determines the level at each frequency by using the detectors and measurement times selected in the measurement settings. In the interactive User Assisted Measurement mode, first the Fine Tuning function is activated for each final measurement frequency. This function allows the user to preselect the local maximum by fine-tuning the receiver and, in case, manually changing the position of the EUT, absorbing clamp / slideway and / or antenna (FIG 6).

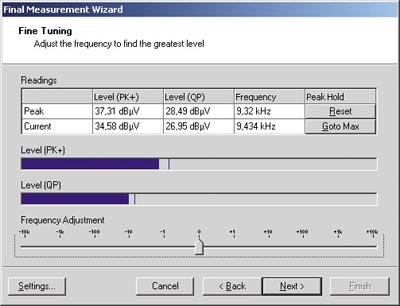

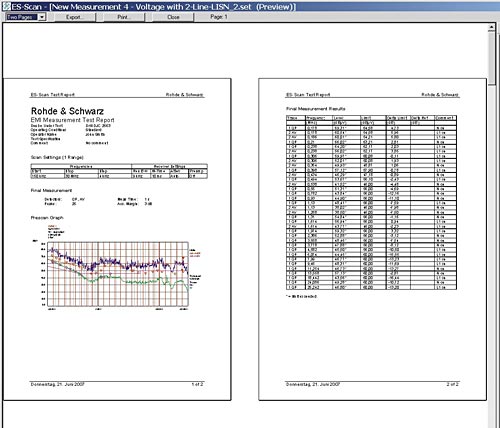

FIG 6 The Fine Tuning function with its additional Maximum Hold display supports interactive measurements. Producing an informative documentation of settings and measurement and analysis results is in most cases quite time-consuming. Also in this respect R&S ® ES-SCAN simplifies and reduces the work of the user. A clearly structured report configurator compiles the individual components of the documentation (general information, receiver settings, graphics, final measurement result) as required. Before being printed the layout can be checked by means of a preview function (FIG 7).

FIG 7 The Preview function enables the user to review the test reports before they are printed. The software controls the R&S ® ESPI receiver either via the IEC/IEEE bus interface or via the optional Ethernet interface (R&S ® FSP-B16 option) as soon as the hardlock copy protection supplied with the software has been plugged into a USB interface of the controller. In the absence of a test receiver, the software simulates all functions in the demo mode in which the user may, for example, generate measurement settings, limit lines, transducer tables and reports or evaluate stored measurement results. SummaryThere is frequently the demand for an efficient and economical application software whenever the EMI measurement task at hand is not the final certification of a product but the examination of the EMC properties of a product under development or the preparation of compliance measurements. In this case, the new R&S ® ES-SCAN software in conjunction with the R&S ® ESPI test receivers represents an excellent solution that makes final certification measurements a pure formality. Author(s): Karl-Heinz Weidner Issue: KIPiS 2008 #3 Related Information:

Companies' news

KIPiS articles

|

Current issue

Search

|

|

|

| © "Test & Measuring Instruments and Systems" ("KIPiS"), 2000-2024 |